Port Arthur Pottery Project Investigation Summary January 2010

Port Arthur Pottery Project Investigation Summary © PAHSMA 2010

History

It is unclear when the brick works and pottery at Opossum Bay began operations but it is known that by May1831 activity had commenced as the southern limit of the settlement at Port Arthur was

described as, “The Rocky Point near the kilns in Opossum Bay” (CSO1/551/12027). In October 1831 William Barton is listed as the first brick maker at Port Arthur (CS01/511/11180). From earlier government correspondence it is known that William Barton had previous experience in the pottery industry and in 1828 applied to be placed in charge of the Government Pottery on Maria Island (CSO 1/76/1685/167).

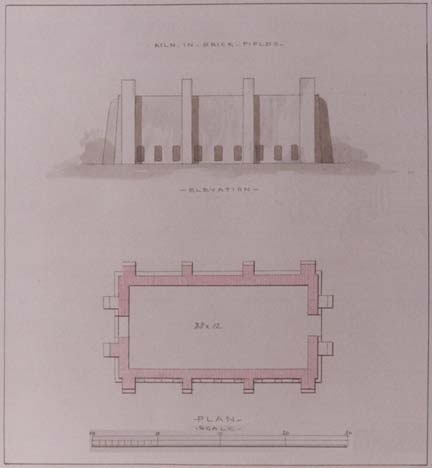

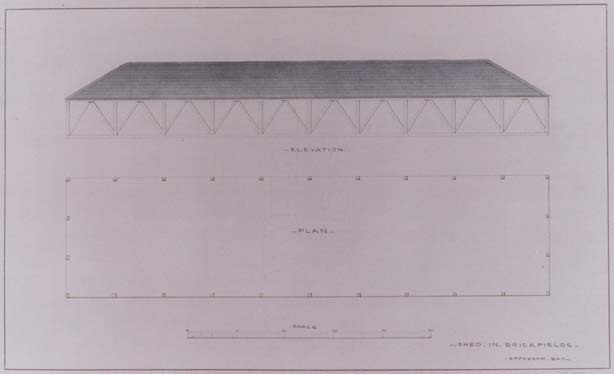

In the buildings survey of the Tasman Peninsula conducted by Henry Laing in 1836 two structures are depicted at Opossum Bay; a substantial brick kiln and a large drying shed. The kiln is shown as measuring 28 feet x 12 feet internally and was enclosed by walls 2 feet thick at the base (tapering to 18 inches at the top). The drying shed is shown as 100 feet in length by 25 feet wide and was open on all sides. No other kilns or structures are depicted for the site, so if any pottery was being produced in this period it must have been fired in the brick kiln. From 1837 onwards architectural ceramics such as flat tiles, gutter tiles and paving tiles are listed as exports from the site (CS05/178/7230).

The kiln depicted by Laing at Brick Point is a typical Scotch kiln, an intermittent updraft type that was common in the UK during the period. A kiln of the dimensions depicted would take about a week to complete a cycle (load, burn, cool and unload), and contain up to 40,000 bricks, depending on the skill of the stacker. It was common practice to only use the kiln once per month.

Brick drying shed at Brick Point depicted by Laing

It is believed that domestic pottery ware was being produced at Opossum Bay by 1840, as flower pots are mentioned in the Port Arthur returns for that year (CSO49/8). In 1842 David Burns visited Port Arthur and published an account of his excursion. He stated that, “There is a factory hitherto

overlooked, where bricks, tiles, gutter tiles, flower pots and other similar articles are manufactured. From the excellence of the clay, the commodities are of the most superior quality, so much so that the use of a pug‐mill and a careful selection of material might prove the means of creating a pottery of infinite value, whence a ware little inferior to Wedgwood might be produced” (Burn, 1972). The absence of a pug‐mill, would mean that any material manufactured in this period would have had large inclusions and other impurities and therefore would be unlikely to be glazed.

Returns for 1841 indicate 962,000 bricks, as well as 15,500 gutter tiles, 1200 paving tiles and 474 flower pots were produced by an average of 26 brickmakers. This equates to approximately 140 bricks plus a couple of drain tiles per man per day, or about 500‐700 bricks per moulding stool – as the men would work in teams. This may be compared with upwards of 3000 bricks per stool per day within a typical UK brickworks of the period.

Some time between 1842 and 1846 the brickworks was relocated to what become known as Brick Field Hill near the northern entrance to the Port Arthur Historic Site (MM62/17 A1107 File 5898). It is not known if the pottery works also moved to the new site. Records, or rather the lack of them suggest that pottery‐making was neglected for a time, as in the visitors book dated March 1856 one J.L Rogers commented “I cannot but notice the value of the Pottery works, and at the same time, express my regret that they should lately have been in some degree discontinued; I think they might be most usefully extended” (C0280/741/335). A subsequent review of industries that could be established or extended that was undertaken by Boyd the following July mentions ‘pottery‐ware’.

It is thought that the pottery was improved and extended in the period 1857‐1858, as the returns for the year ending June 1858 record that 340 glazed cell pans were manufactured as well as 270 flower pots and 170 insulators (C0280/746/341). This is the first mention of glazed material being produced at the pottery for which a pug‐mill most likely would have been required. The same return records the production of 183,000 bricks in 2200 convict days. Throughout the 1850s and 1860s annual returns report the production of between 100,200‐200,000 bricks per annum, sufficient for only half a dozen or so kiln firings.

Some time around 1867 brickmaking appears to have been discontinued at Brick Field Hill, and

recommenced at Opossum Bay. (The shed at Brick Field Hill collapsed in August of that year and the Commandant wrote a terse note to George Eastman to ask him to stop his children cutting it up for firewood ‐ Tas Papers 315, 11/9/1867) Bricks, tiles and pottery goods thereafter appear sporadically in station returns until the early 1870’s. In March 1870 the Mercury reported “About three‐quarters of a mile further off are the Brickfields and pottery, where excellent bricks are made for the erection ofbuildings and some exceedingly pretty pottery has been turned out. We saw a large quantity of flower‐pots intended for Government‐house, which were equal to any made in the Colony. Milk dishes and other articles are manufactured here” (Mercury 25/3/1870).

It is not known when the pottery (and brickworks) at Opossum Bay ceased operating, but given the

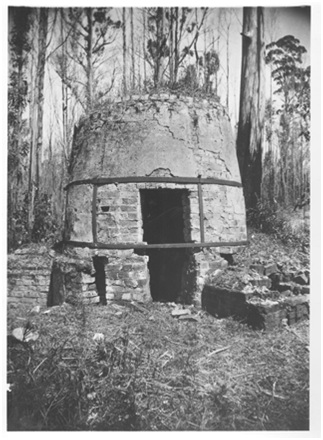

extent of recycling taking place during the final years of the station’s life it is likely that the brickworks if not the pottery was closed well before 1877. Photographs attributed to E.R Pretyman dated c1880s of a pottery kiln at Opossum Bay shows the structure in significant disrepair.

It would be another decade or more after the closure of the penal station that pottery making returned to Port Arthur. In 1886 James Price, who had arrived from the United Kingdom in 1884, brought three lots on Peel Street, Brick Field Hill, totalling 3 acres 12 perches. It is unclear what remained of the convict works by this time and whether James Price scavenged material to build his own kilns (one of which survives), and whether he re‐occupied the site of the earlier convict works. James Price died at Port Arthur in 1912 and during his time at Port Arthur produced mainly decorative terracotta and other unglazed as well as glazed types of earthenware.

Archaeology

An archaeological investigation of Brick Point has been on the drawing board for some time, but was given impetus following PAHSMA’s receipt of a proposal from an external researcher (La Trobe

University archaeology PhD student Anthony Bagshaw) who wished to study evidence of early

pottery manufacture in Australia. As we didn’t have any examples of definite convict‐made pottery

within the existing collection we decided to carry out some test excavations at Brick Point (and Brick

Field Hill) with a view to identifying what sites might exist on PAHSMA managed land and to

recover examples of convict‐made pottery for comparative analysis.

As we didn’t have much information about the site we had to complete a topographic survey of the

site in preparation for a more detailed geophysical survey to help pinpoint possible targets for

excavation.

An opportunity to carry out this work arose as a result of a fire that burned the north side of Brick

Point in Spring 2008. Further clearing was done manually in November 2008 by CVA volunteers,

which exposed the site’s major remaining structural feature. The area was mapped topographically in December and selectively gridded and geophysically surveyed using a magnetometer in December and January.

Excavation of a test trench over the magnetic anomaly revealed the existence of a brick paved floor, surrounded by a deep cutting corresponding to the footing trench for the 1836 depicted kiln. The subsoil beneath the brick floor was baked, indicating the application of considerable heating and providing the source of the magnetic anomaly.

Anecdotal information indicates that bricks were taken from this area during the 1930s to build a pair of lime kilns further south adjacent to Safety Cove Road. The remaining trenches represent the

robbed‐out foundations of the original convict brick kiln.

To the north of the brick kiln, a semi‐circular depression was also investigated by test trenching. This feature was located within a scatter of locally made pottery sherds. The sherds indicate that a range of pottery wares were being produced, variously with plain finish, glazed, or impressed/incised decoration. Forms include flowerpots, open and lidded storage containers, and larger open pans.

The depression was heavily disturbed by tree growth andbank collapse, however it was initially thought that it maybe the site of a dedicated pottery kiln; a separate structurebuilt c.1840 and photographed c1880. Subsequent excavatiorevealed that while that site demonstrated convict landbuilding activities, possibly to create a level space for the pottery to operate, the surface depression was unrelated to the pottery works.

Excavation of Trench 2 over a pronounced circular depression,

revealed convict-era brick dumps and land-levelling activities. The

depression was determined to be the result of a later disturbance, unrelated

to the pottery.

The circular structure depicted in the c.1880

photograph taken at

Brick Point is a Staffordshire-type

bottle kiln, although without the

distinctive external

bottle-shaped hovel. The kiln is updraft, with

at least

three, but almost certainly more, fire mouths. These

appear

to have been modified, possibly to facilitate the

use of wood as

fuel.

Port Arthur Pottery Project Investigation Summary © PAHSMA 2010

|